.png)

In the mid-1980s, a site in the East of England suffered a significant leakage of the chlorinated solvent Perchloroethylene (PCE), causing land and groundwater pollution. Because the density of these kinds of solvents is greater than water, they tend to sink in groundwater systems, resulting in complex plume patterns which can make leakages such as these difficult to remediate.

Attempts were made to remediate this site via vacuum extraction and by a deep pump and treat system. However, the legacy of solvent pollution can be substantial and enduring and, after around 30 years of pumping, little improvement had been seen at this site.

GEA was contracted initially a few years ago to investigate the extent and 3D distribution of the plume within the underlying chalk aquifer using a Membrane Interface Probe (MIP), video cone and several multi-level sampling point wells. Following this site investigation, an initial trial phase of the remediation was designed and implemented by Regenesis, which involved the direct injection of a wide-area distribution staged-release electron donor (3DME). This injectable liquid material is designed specifically for in situ remediation projects, transforming problematic chlorinated solvents in groundwater into less harmful end products. A micron sized sulfidated zero valent iron (S-Micro ZVI) was also injected into the central plume area, to reduce contaminants within the subsurface environment.

The GEA team was subsequently contracted to investigate the effectiveness of these remediation treatments via a long-term groundwater monitoring programme, involving further MIP and video cone sampling, plus Monster Steek Apparaat (MOSTAP).

Currently, in order to allow vertical profiling of the plume and to confirm the distribution of the remedial agents within the chalk aquifer, we are carrying out six months of validation monitoring using zero purge Discrete Interval Sampling (DIS) along with low flow sampling from Solinst CMT multi-level sampler installations.

As Discrete Interval Samplers, or passive samplers, are sealed when lowered and also upon raising for retrieval, they are designed to collect groundwater samples from a specific sampling zone. As DIS prevents water from mixing at different levels and removes the need for purging, it provides the optimum technique for ensuring representative results are obtained, throughout the water column even at depth, whilst ensuring that the sample chemistry remains intact.

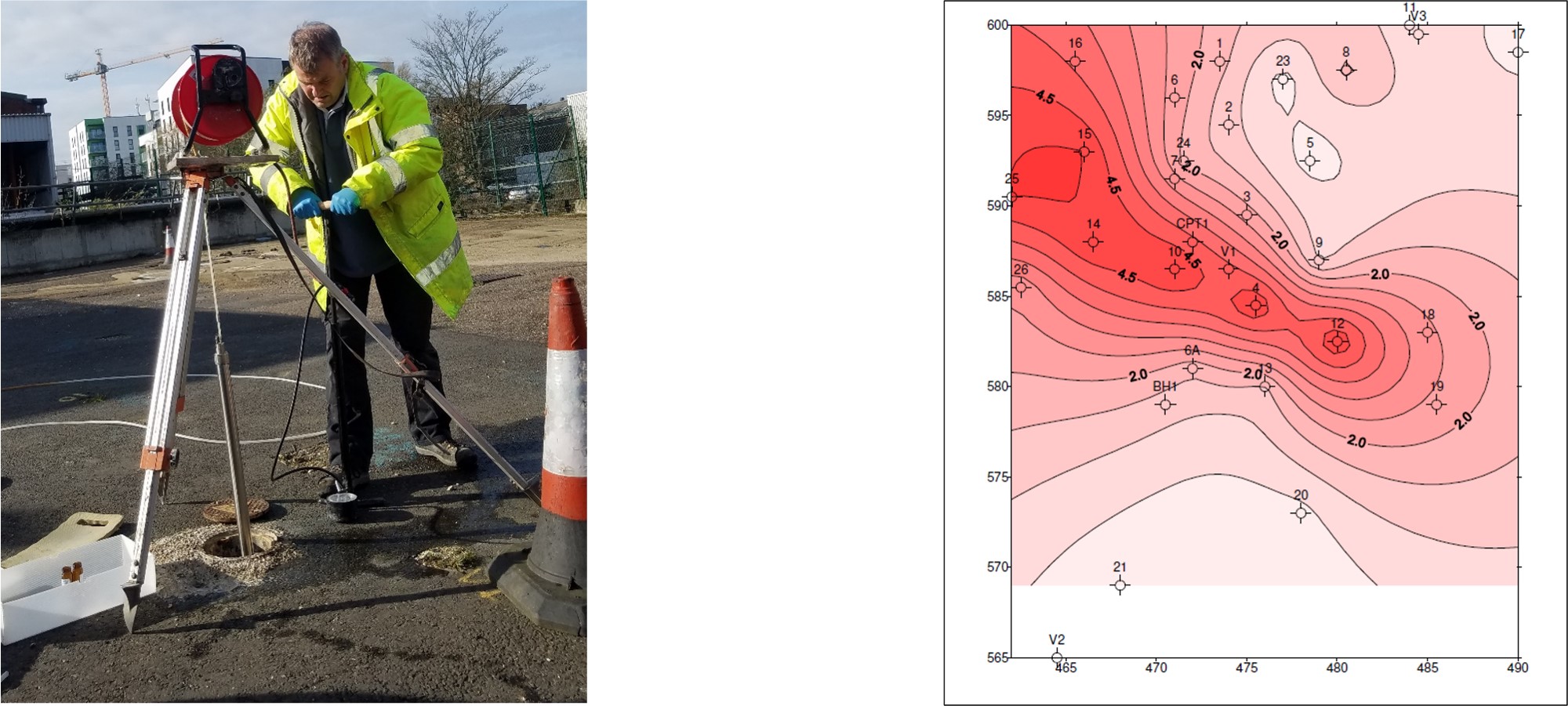

Mike Plimmer - Technical Director at GEA - on site in the East of England, using the Discrete Interval Sampler to carry out vertical profiling through the Perchloroethylene plume. And, mapping of the contaminant plume using the Membrane Interface Probe (MIP) response at 6m to 8m depth.

The data from the first year of monitoring is very encouraging, suggesting that full reductive dechlorination is occurring within the centre of the plume. However, investigations have highlighted some zones that do require further targeted treatment.

Our team is interpreting this data to assist Regenesis in the design of the full-scale remediation of the plume, which should allow the cessation of the existing pumping scheme, which is currently attempting to ‘contain’ the plume. We will continue to monitor these additional works to provide full validation of the remedial scheme.

Our experience of identifying contamination on a site and designing a strategy for remediation, as well as first-hand knowledge of a wide range of available remediation methods and technologies, means that we are able to advise our clients on the most appropriate method of dealing with contamination problems.

If you have a project you’d like to discuss, please get in touch. We’re always happy to share our expertise.

Related News